Shrink tubing is a fairly new type of packaging material used in food processing. This type of packaging materials is used for the new generation automatic loaders that convert shrink tubings to bags.

MPSYSTEM manufactures shrink tubing for maturation and storage of food products such as cheese, fresh and processed meat.

MPSYSTEM tubing is produced by co-extrusion and consists of several layers, each of which provides the tubing with appropriate properties (e.g. mechanical, barrier, optical, shrink, etc.). The PVdC layer is used as a barrier layer that provides appropriate barrier properties that are independent of product and environment humidity, which is an important advantage for food producers.

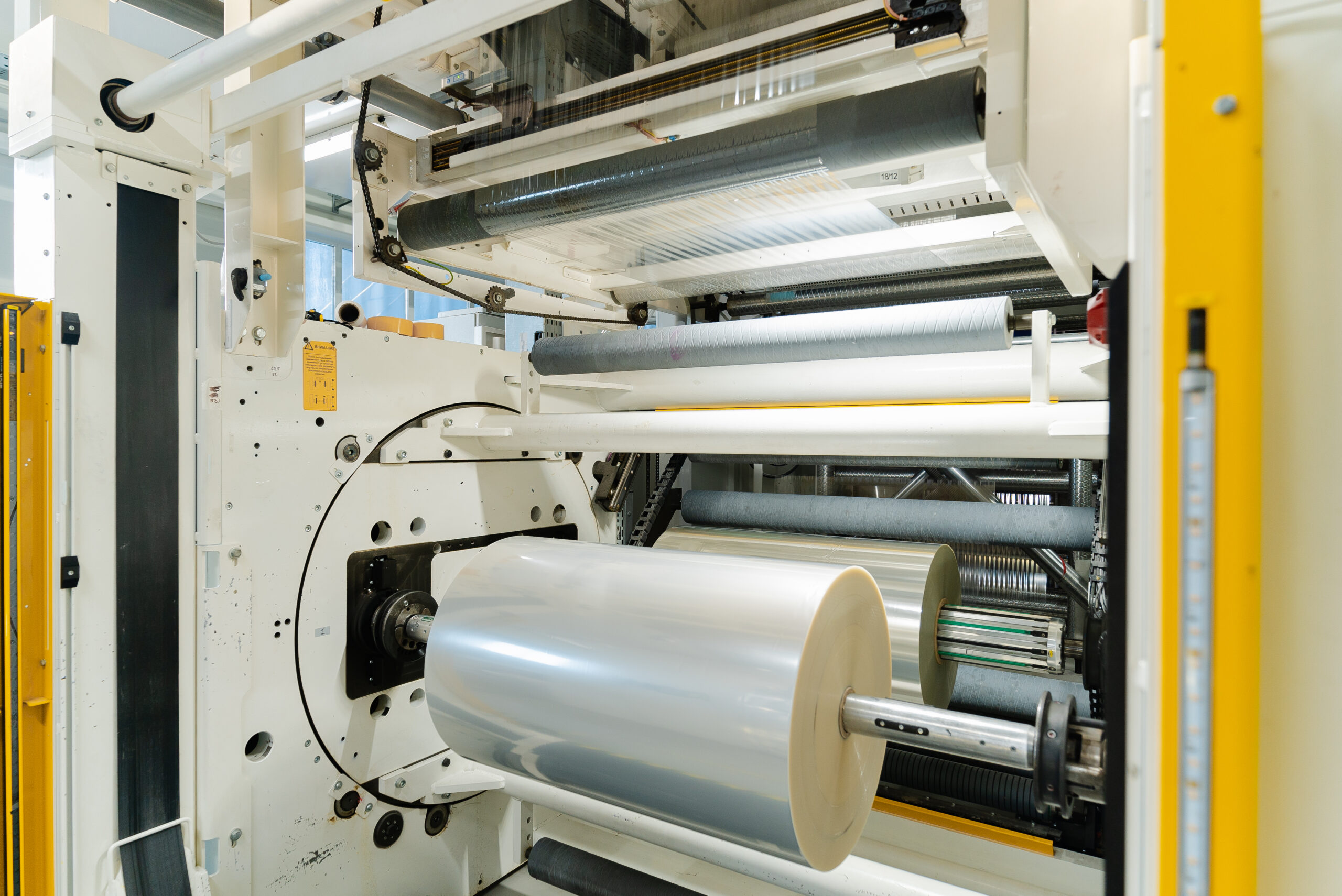

The modern equipment and exclusively raw materials approved for food contact are used for the tubing manufacturing.

The production process fully complies with all local and EU safety requirements and is continuously monitored by the Quality Department using laboratory equipment.

product protection from contamination

product protection from oxygen (O2) to extend the shelf life of the product.

release of excess carbon dioxide (CO2) generated during cheese maturing (for “low” and “medium” barrier tubing)

product moisture loss protection (water vapor barrier)

product presentation and differentiation due to the optical properties of the tubing and the possibilities of printing

protection against leakage (hermetic packaging)

packaging automation and efficiency

MPSYSTEM tubings main characteristics:

| Available tubing width: |

180 – 500 mm |

| Tubing thickness: |

40 – 50 µm |

| O2 barrier type: |

ASL50L low barrier ASL50 medium barrier ASL50H high barrier |

| Material color (pigment): |

10 colors + transparent |

| Tubing printing option: |

10 color flexo printing |

| Roll length: |

up to 2 km |

We provide innovative, sustainable packaging solutions that protect and extend the lifecycle of products.

Ask one of our experienced Customer Care representatives. We are happy to help you find the perfect solution.